Component Catalogue¶

The component catalogue schema contains information regarding the components that are used to create complete packages. These maybe created from a single material or a combination of materials from the materials schema.

Table¶

| Column | Status |

Format | Notes |

|---|---|---|---|

| identifier | required |

String | A globally unique identifier. See identifiers section for information on how to construct this identifier |

| name | recommended |

String | The name of this component. |

| description | recommended |

String | A brief description of this component. |

| tags | recommended |

Dictionary | A dictionary of identifiers that might be used to identify the component in other systems. For example: bar codes or global trade item number (gtin). To provide tags please follow this format. {'tagName1': 'identifier1', 'tagName2': 'identifier2'} |

| imageURL | recommended |

URL | A URL that links to a picture of the component. Please see the guidelines below on how to capture the image and name the URL. |

| LOWcode | recommended |

String | The list of waste code for only the component, by itself. LOW code is synonymous with European Waste Catelogue Code (EWC). For example: an empty bottle would have a LOWcode of 15 01 02. Please use Dsposal or legislation.gov to find the LOWcode. Note: The LOWcode can based on its combination with other components and the actual product contained in the completePackaging. Be sure to only include the component LOWcode. If you cannot find the code or are uncertain please enter Uncertain. |

| materialIdentifier | required |

String | The unique identifier of the materials that this component is made of. There must be an equivalent record in the materials data. |

| height | recommended |

Numeric | The height of the component. Please see the guidelines below on how to properly measure and report the height. |

| heightDate | recommended |

String | The date that the height was last verified/measured. Use the format dd/mm/yyyy. |

| width | recommended |

Numeric | The width of the component. Please see the guidelines below on how to properly measure and report the width. |

| widthDate | recommended |

String | The date that the width was last verified/measured. Use the format dd/mm/yyyy. |

| depth | recommended |

Numeric | The depth of the component. Please see the guidelines below on how to properly measure and report the depth. |

| depthDate | recommended |

String | The date that the depth was last verified/measured. Use the format dd/mm/yyyy. |

| volume | recommended |

Numeric | The amount of space the component takes up. Note: this is related to the size of the component and is different to capacity. Using the height, width, and depth found using the measurement guidelines, calculate the component’s volume using: height x width x depth. |

| volumeDate | recommended |

String | The date that the volume was last verified/measured. Use the format dd/mm/yyyy. |

| weight | required |

Numeric | The weight of the component. |

| weightTolerance | required |

Numeric | The threshold of weight that components can vary by. This is given as +/- x%. |

| weightDate | recommended |

String | The date that the weight was last verified/measured. Use the format dd/mm/yyyy. |

| shape | recommended |

String | What is the shape of the component? The entry should contain the shape controlled list identifier for the component. |

| function | recommended |

String | What is the function of the component? The entry should contain the function controlled list identifier for the component. |

| flexibility | recommended |

String | Whether the component is considered flexible or rigid. The entry should be the flexibility controlled list identifier. |

| branding | required |

Boolean | Does the component contain your own brand (logo, trademark, or any distinctive mark)? |

| componentRecyclingDisruptors | recommended |

String | What challenges the component has for recycling. The entry should be the componentRecyclingDisruptors controlled list identifier. |

| colour | recommended |

String | The actual colour of the component at point of production using CMYK (Cyan-Magenta-Yellow-blacK) values. The format is specified according to cmyk(C%, M%, Y%, K%), where C, M, Y, and K are the percent values for the cyan, magenta, yellow, and black values of the color. For example: black is cmyk(0%,0%,0%,100%). |

| opacity | recommended |

String | The transparency of the colours. The entry should be the opacity controlled list identifier. |

| loaned | required |

Boolean | Is the component hired or loaned out as reusable packaging? |

| reuseSystem | recommended |

String | The system that facilitates the reuse of the component e.g., Loop |

| manufacturedCountry | required |

Numeric | The country the component was manufactured in. Use the country numeric ISO codes as described in the ISO 3166 international standard. |

| recycledContent | required |

Numeric | The minimum allowable percent of how much recycled content is included in the makeup of the component. For the purposes of this standard, we refer to the UK’s HM Revenue & Customs definition of recycled content. “Recycled plastic is plastic that has been reprocessed from recovered material by using a chemical or manufacturing process. This is so it can be used either for its original purpose or for other purposes. This does not include organic recycling. Recovered material is pre-consumer plastic or post-consumer plastic that both: a) is no longer suitable to be used in the process from which it was generated and would otherwise have been used for energy recovery (for example, by incineration) or disposed of as waste (for example, by being sent to landfill); b) has been collected and recovered for use as a material input for a recycling or manufacturing process, instead of new primary material” |

| recycledContentEvidenceType | required |

String | What evidence type supports the recycledContent claim. The entry should be the recycledContentEvidenceType controlled list identifier. |

| recycledContentEvidenceReference | required |

String | An accompanying reference number associated with the recycledContentEvidenceType for the component. |

| recyclability | recommended |

Boolean | Is the component recyclable (as determined by a reputable source)? |

| recyclabilitySource | recommended |

String | What source provided the recyclability claim? The entry should be the recyclabilitySource controlled list identifier. |

| recyclabilityDate | recommended |

String | The date that the recyclability was provided/last updated. Use the format dd/mm/yyyy. |

| partOfMultipack | required |

Boolean | Is the component part of a multipack? Answer as: 1 for yes and 0 for no. |

| previouslyAssembledComponent | required |

Boolean | When manufactured, was this component combined with other components? Answer as: 1 for yes and 0 for no. |

| componentLink | required |

String | If previouslyAssembledComponent is yes, please provide the identifier for the component that is attached when created. Answer NA if previouslyAssembledComponent is no. |

| updateDate | required |

String | The date that the component was provided/last updated. Use the format dd/mm/yyyy. |

| releaseDate | recommended |

String | The date that the component will be available to use. Use the format dd/mm/yyyy. |

| discontinueDate | recommended |

String | The date that the component will no longer be available to use. Use the format dd/mm/yyyy. |

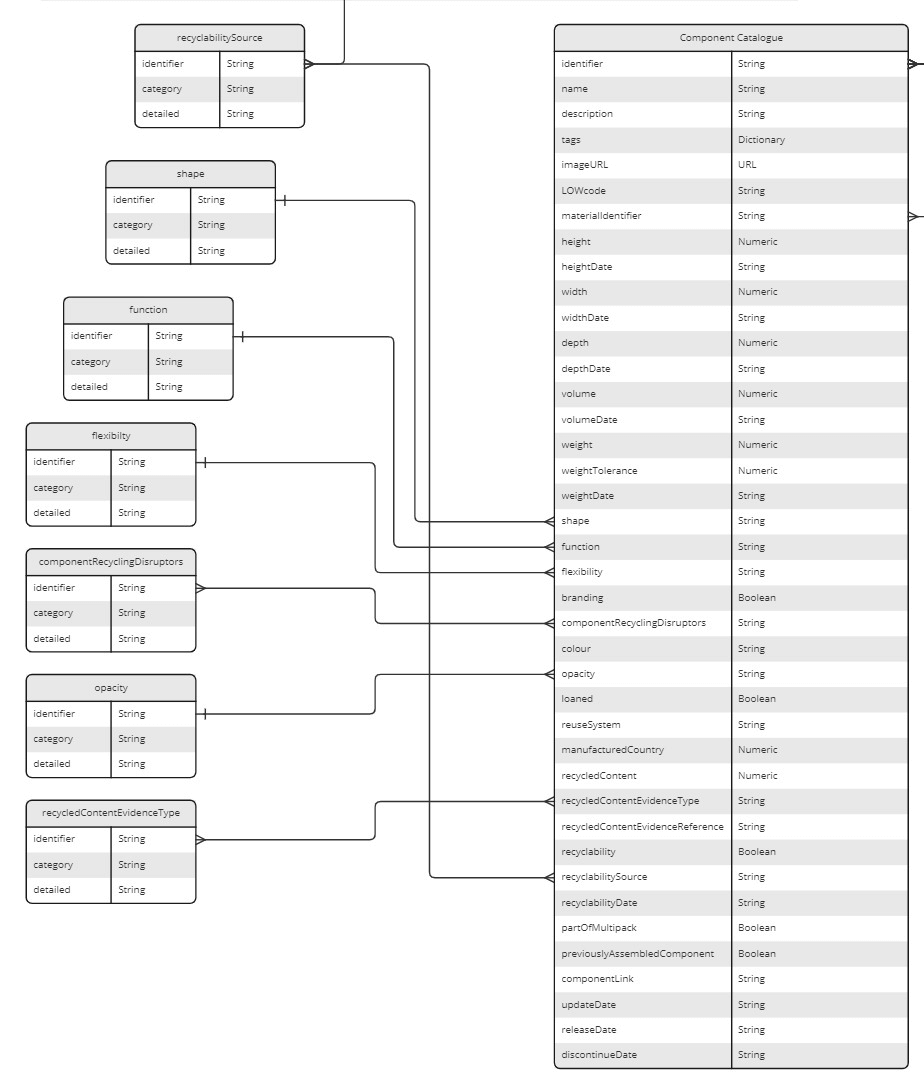

Diagram¶

Template¶

Components should be provided as a separate csv file, in tidy format. This means that each row of the csv file should be one component of a complete package. An example is provided.

The specification of this csv file is as follows:

Component_Catalogue_Template.csv

Example¶

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 | |

Guide for how to take measurements¶

Units¶

All measurements should be given using the metric system.

- Height: millimetre (mm)

- Width: millimetre (mm)

- Length: millimetre (mm)

- Volume: cubic metre (m3)

- Weight: grams (g)

- Weight Tolerance: percent (%)

Numbers should be entered with a decimal place. Use the decimal / full stop / period character as a separator. Do not exceed 3 decimal places. When rounding, use convential rounding methods: for 5 and above round up, 4 and below round down. For example: volume = 0.67952 rounded to 0.68.

Important: When converting between systems of measurement, perform the conversion first and then apply the convential rounding. This will give more accuracy and consistency.

Default Front of a component¶

Prior caputuring measurements, first determine the default front of the component, this is similar to GS1 (Note: GS1 rules are specified only for complete packaging and not components. Therefore, there are subtle differences to convert from taking a measurement for the complete packaging versus a component). In this standard, as with GS1, the default front is the face with the largest surface area, where area is equal to the width times the height.

Important: Determining of default front provides a consistent, repeatable process to find measurements for a given component.

width X height)Some components have the same surface area, thus more than one possible front. These components can be presented both vertically and horizontally. If a component has more than one possible front, the highest side is considered to be the default front.

Note: Calculating the area for a rectangular component is simple. However, for non-rectangular components (for example, components with a cylindrical or irregular form), the method to calculate the area is:

- First break the component into multiple sides. Then, for:

- a round component: do not use (=pi*r^2) to calculate the area. Instead, draw “two dimensional” rectangles around the round component’s sides and then calculate the area for each side.

- any other shape component: draw a “two dimensional” rectangle around the sides of the component, and then calculate the area for each side.

- The side with the maximum area then becomes the default front of that component.

width X height)Measuring the height, width, and depth of a component¶

After the default front has been determined, as with GS1, it is possible to determine the height, width, and depth of a component.

- For rectangular components:

- Height: from the base to the top

- Width: from the left to the right

- Depth: from the front to the back

Note: If there are two different measurements for the height, width, or depth, always report the maximum measurement.

-

For irregular shaped components: Similar to finding the default front of an irregularly shaped component, draw a “three dimensional” rectangle around the component.

- Height: from the base to the top

- Width: from the left to the right

- Depth: from the front to the back

-

For unformed, flexible components:

- Take the measurements as if the component was fully formed and filled.

-

For standing components:

- Height: from the flat surface to the top most point

- Width: from the left-most point to the right-most point

- Depth: from the default front to the farthest opposite surface

-

For components with leaning or irregular verticlas:

- Height: from the flat surface to the top most point (parallel to the vertex)

- Width: from the left most point to the right most point

- Depth: from the default front to the farthest opposite surface

-

For components that are cylindrical:

- For cylindrical items two dimensions will be nominally equal. Which dimensions are equal is determined by the result of determination of the default front.

Guide for component images¶

As with providing measurements, please first find the default front of the component. The image capturing process and naming convention is similar to GS1. As with measurements, we altered the gs1 standard for capturing the component.

Type of Image¶

For the purposes of this standard, we define the differences between photographic and rendered images. Note: both types are accepted but the naming convention will differ based on image type so that images have unique names and do not having naming conflicts.

- Photographic image: the result of the electronic or chemical capture of a likeness of a physical object with the use of a camera.

- Rendered image: the result of the creation of a digital likeness of a physical object with the use of a computer and software.

Image Recommendations¶

- Provide coloured images. However, do not provide colour casts. Colour should be as rich, vibrant and eye-catching as possible

- Contrast and exposure should be balanced; avoid high contrast effects and “blown-out” highlights

- Images should not be overly sharpened

- Components should be centred in Margins to cover 95% on the canvas.

- Graphic rendering of a component should be realistic.

- Do not provide layers, guides or rulers in the images.

- Background layer should be white (RGB 255,255,255).

- Remove signatures, “finger printing” or visible watermarks. No compression artifacts. No interpolation (“resizing up”).

File size¶

- 900x900 to 2400x2400 pixels

Component faces¶

After determining the default front, the possible faces, in relation to the default front, are: 1. Default Front 2. Left 3. Top 7. Back 8. Right 9. Bottom

Naming convention for URL¶

Please follow this naming convention:

- component identifier

- underscore _

- type of image (photographic or rendered)

- underscore _

- component face (1: Default front, 2: Left, 3: Top, 7: Back, 8: Right, 9: Bottom)

- orientation (C: Centre, L: left, R: right, N: No plunge angle)

Example: An image for a component that is rendered with a default front facing image and centred orientation. identifier123_rendered_1C.jpg